Get Support

123-456-789-10

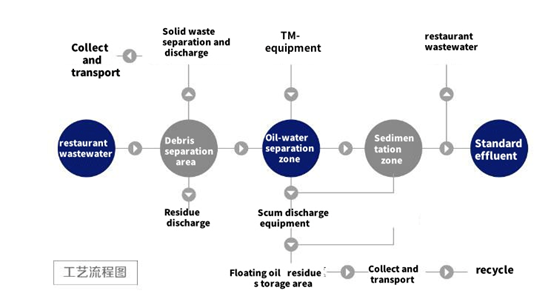

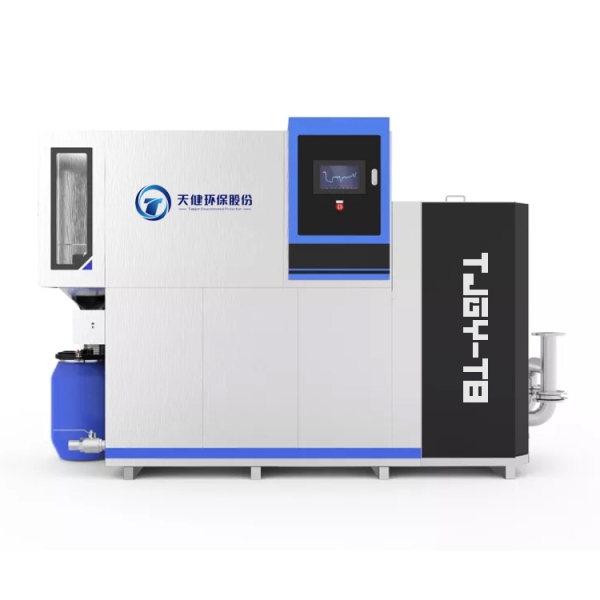

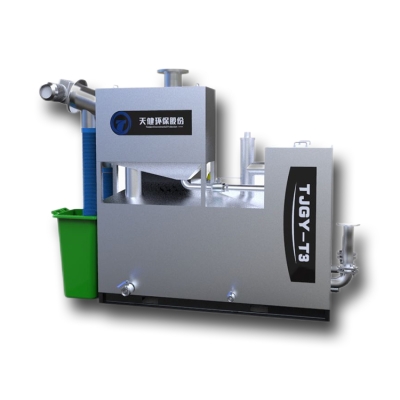

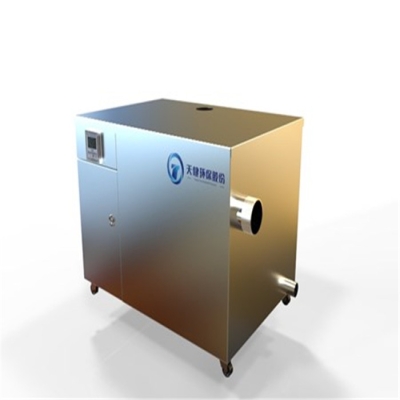

The TJGT8 Series Automatic Grease Trap utilizes MNB technology, adopting a full-section flow method. This system integrates a newly invented self-cleaning slag discharge device, a bottom separation structure, and a wheel-type oil scraping mechanism. These features enable the equipment to perform slag-water separation, oil-water separation, and wastewater lifting, ensuring the standard discharge of catering wastewater.

Our automatic grease traps are engineered to improve the efficiency and hygiene of kitchen waste management. By integrating automatic grease traps with modern technology, such as IoT and big data, the TJGT8 transforms from a traditional grease trap to a highly efficient smart system. It offers an environmentally friendly solution that eliminates odors, reduces energy consumption, and simplifies maintenance.

Key Features of the TJGT8 Automatic Grease Trap:

- Advanced Technology: Equipped with MNB technology and a self-cleaning slag discharge system for more efficient operation.

- High Efficiency: Integrates smart technology like IoT and app support for easy monitoring and management of the grease trap.

- Environmentally Friendly: No peculiar smell, low energy consumption, and pollution-free operation.

- Space-Saving Design: Compact and easy to install, making it perfect for hotels, restaurants, and canteens.

- Low Maintenance: Simple management and maintenance, which results in high economic efficiency and reduced downtime.

Applicable Fields:

Our automatic grease traps are ideal for catering wastewater disposal and lifting in environments like restaurants, hotels, and canteens. These commercial kitchens often face challenges with oil and grease buildup, and the TJGT8 is designed to effectively manage wastewater while maintaining high hygiene standards.

Why Choose TIANJIAN’s Automatic Grease Traps?

- Advanced Self-Cleaning Mechanism: The integration of self-cleaning slag discharge and oil scraping ensures consistent performance and less manual intervention.

- Smart System Integration: Leverages IoT and big data to offer a smart solution that reduces energy consumption and enhances system monitoring.

- Reliable Wastewater Disposal: Ensures standard discharge of catering wastewater, preventing clogging and contamination.

- Economically Efficient: Low maintenance cost and high performance make this solution both cost-effective and sustainable.

For more details on our automatic grease traps, visit our Catering Oil Water Separation Equipment page.

Contact Us for More Information

Looking to improve your kitchen’s wastewater management with automatic grease traps? Contact us today for more details or to receive a customized quote for your business needs. Get in touch here.

Utilizing MNB technology, adopting a full-section flow method, combining a newly invented self-cleaning slag discharge device with a bottom separation structure and a wheel-type oil scraping mechanism, which can realize the functions of slag-water separation, oil-water separation, and wastewater lifting. To achieve the standard discharge of catering wastewater.

Applicable field:

Catering wastewater disposal and lifting in restaurants, hotels and canteens.

The TJGT8 series automatic grease trap transform from functional to efficiency, which can integrate APP, IoT, and big data technology to jointly create an upgraded product of smart grease trap. The equipment covers a small area, does not produce peculiar smell, does not pollute the environment, has low energy consumption, simple maintenance and management, and high economic efficiency in use. It solves a series of problems of serious acid and odor, scraping residue and oil with water, low efficiency, overflowing adhesion and clogging, more sedimentation, narrow flow channel, and substandard water discharge.