Get Support

123-456-789-10

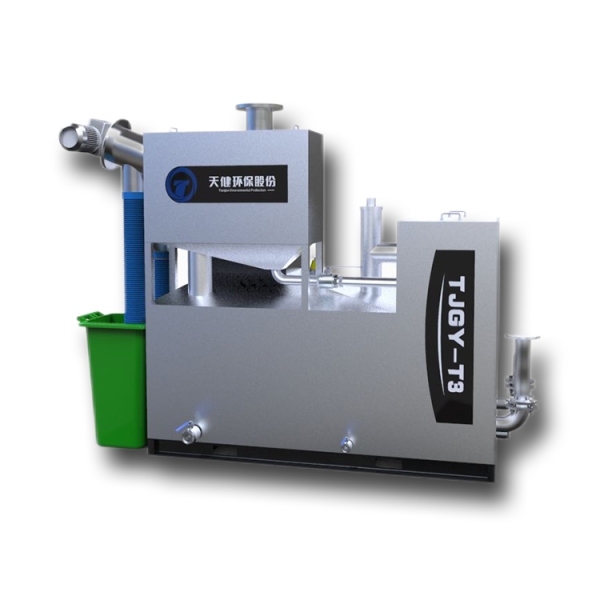

The TJGT3 automatic grease trap equipment

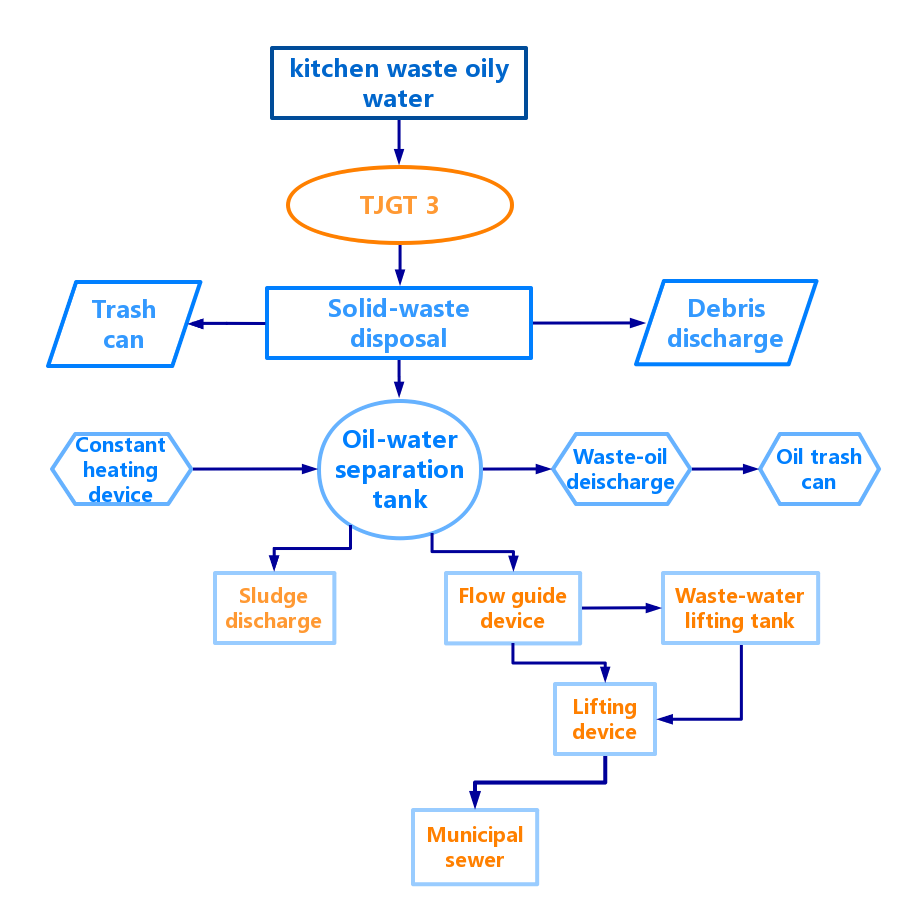

The TJGT3 automatic grease trap equipment adopts a new processing technology, which first removes slag and then sludge, and then enters the conical oil-water separation tank to separate the oil and water. It has the functions of hydraulic oil drainage, automatic electric heating, and oil separation

- Model: TJGT3

- Brand: TIAN JIAN

- Port:

- Quantity:

Applicable field

Hotels, restaurants, large supermarkets, food courts, school canteens, commercial

The product has obtained CE certification and UL certification

CORE ADVANTAGE

①Using the principle of gravity, grease skimmer built-in.

②Equipped with a constant temperature device to ensure that the grease will not agglomerate at low temperatures.

③Separate discharge and storage of slag, oil and water

④Double pump lifting to ensure the stability of drainage

⑤Low energy consumption, saving money.

1. How to ensure the effectiveness of oil-water separation?

Tianjian's "TJGT3 series fully automatic oil separation and lifting intelligent equipment" adopts a hierarchical oil-water separation process upgraded from the sixth stage oil-water separation process of the third-generation T3 series oil separation equipment, effectively removing 80% of floating oil and 15% of emulsified oil in the oil. The oil content in the effluent is less than 100mg/L, which meets national standards.

2. Where does water come from? Where did it come from again? Is installation convenient?

TJGT3 series fully automatic oil separation and lifting intelligent equipment "is an intelligent product specially designed by Tianjian Company for the treatment of underground catering wastewater. The equipment only needs to be simply connected to the inlet and outlet of the equipment during installation, and can operate stably when powered on. Installation is very convenient!

3. How to control the generation and spread of odors?

The fundamental reason for the foul odor of catering oil separation equipment is that food waste is not cleaned up in a timely manner, and after entering the oil-water separation chamber, it undergoes long-term fermentation, resulting in the production of fatty acids and causing foul odor. Our Tianjian company's oil separation lifting equipment has undergone three-level treatment in the early stage to remove odors, and with sealing and ventilation measures, we have created a conscientious product that is odorless, environmentally friendly, and reliable.

4. How to discharge grease?

Tianjian's "TJGT3series fully automatic oil separation and lifting intelligent equipment" has changed its design concept from the traditional three-stage oil separation that requires manual salvage. It uses the asymmetric conical structure above the oil-water separation zone to concentrate the oil, and then uses a chain automatic oil discharge mechanism to discharge it into a dedicated closed oil drum for centralized transportation. It basically does not require manual salvage of floating oil and emulsified oil, and has low operating costs and high efficiency. The equipment comes with a constant temperature electric heating device, which avoids the disadvantage of animal fat solidification and smooth discharge; The equipment also comes with a manual oil discharge device.

5. How does the control system work?

The intelligent management and control system of Tianjian's "TJGT3 series fully automatic oil separation and lifting intelligent equipment" adopts PCU microcontroller control, and the operating status is displayed in Chinese. Its highlight is process linkage control: it automatically starts the slag removal machine, oil discharge device, heating device, and drainage device when there is a processing demand according to the processing requirements, without causing waste of power resources. The system adopts a magnetic liquid level detection device and has functions such as multi-point monitoring, automatic alarm, overload and short circuit protection, signal remote transmission (BA interface), and water pump water shortage protection.

| Specification and model | Processing capacity (m³/h) | Installed power (kw) | External dimensions (mm) | Equipment weight (kg) | Effective volume (L) | Lifting height (m) |

|---|---|---|---|---|---|---|

| TJGT3-4 | 15 | 4-7 | 2400x1000x1900 | 500 | 700 | 15 |

| TJGT3-7 | 25 | 4-7 | 2500x1000x2100 | 540 | 1440 | 20 |

| TJGT3-11 | 4-9 | 4-9 | 2700x1000x2100 | 580 | 1620 | 25 |

| TJGT3-15 | 55 | 5-9 | 3000x1170x2100 | 650 | 2190 | 25 |

1. What kind of oil separation lifting equipment is better?

1. No peculiar smell: Due to the chemical and biochemical effects, the grease deposits in the equipment will gradually decompose over time and generate corrosive fatty acids, which will produce a very unpleasant odor and corrode the equipment.

2. Removal of grease in catering wastewater

Prevent the grease and solids in the wastewater from blocking the drainage pipeline, protect the environment, and make the water quality meet the discharge requirements of relevant national and local regulations (the oil content of the effluent is ≤100mg/L), and the drainage system is unblocked.

3. Centralized collection and treatment of waste grease, vegetable rice residue, suspended solids, and solid residues, and recycling of waste grease.

4. The equipment has strong adaptability, capable of continuous stable, reliable and safe operation, and low operating cost.