Get Support

123-456-789-10

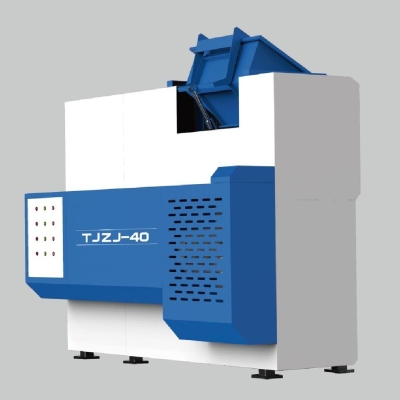

TJCLI Integrated kitchen garbage intelligent treatment equipment system

Tailored for catering environments, this waste treatment equipment ensures sustainable waste handling in restaurants, cafeterias, and food service hubs. Reach out to us for details.

- Model: TJCL

- Brand: TIAN JIAN

- Port: ShangHai

- Quantity: 99+

Catering Waste Treatment Equipment – TJCLI Integrated Kitchen Garbage Intelligent Treatment System

Tailored for catering environments, the TJCLI Integrated Kitchen Garbage Intelligent Treatment Equipment System is designed to provide efficient and sustainable waste handling for restaurants, cafeterias, and food service hubs. This all-in-one machine ensures fast processing, high decomposition efficiency, and low odor, making it the perfect solution for commercial waste management.

Key Features of the TJCLI Catering Waste Treatment Equipment:

|

1 |

Fast and Efficient Waste ProcessingProcessing Time: Achieves up to 90% waste reduction within 4 to 24 hours.High Decomposition Efficiency: Efficiently handles waste with minimal odor. |

|

2 | Wide Range of Waste Materials ProcessedHandles swill waste, fruit and vegetable waste, and other organic materials.Temperature Range: Operates effectively in environments ranging from -20°C to +50°C. |

|

3 | Versatile and CustomizableProcessing Capacity: Can process from 100 pounds to several tons of waste per day, depending on the unit model.Custom Size Specifications: Tailored to your specific venue and requirements, making it ideal for schools, enterprises, government agencies, and other institutions. |

|

4 | Advanced Shredding TechnologyEquipped with a dual-axis metal shredder that easily decomposes kitchen waste, including large bones. |

|

5 | Adjustable Parameters for Optimal PerformanceControl over cabin temperature, inlet air temperature, inlet air volume, and mixing speed for maximum waste decomposition efficiency. |

|

6 |

Modular and Easy to MaintainStandardized Design: The equipment uses modular components that make it easy to install, scale, and maintain.User-friendly: No need for dedicated supervision, making it highly reliable for commercial environments. |

|

7 |

Energy-Efficient Design:Incorporates energy-saving features like heat recovery, insulation, and a high-efficiency mixing system to reduce energy consumption. |

|

8 |

IoT Integration for Real-Time MonitoringThe system is integrated with an IoT big data platform that allows for real-time monitoring, operation, and maintenance, ensuring optimal performance and data sharing across platforms. |

Image of the final product: Nutrient-rich organic fertilizer from processed kitchen waste.

The output is a nutrient-rich organic fertilizer that can be used for agricultural or landscaping purposes, promoting sustainability and enhancing soil quality.

Why Choose TIAN JIAN’s Catering Waste Treatment Equipment?

- Tailored Solutions: Custom-built to meet your specific waste management needs.

- Proven Technology: Advanced features like dual-axis shredding and IoT monitoring.

- Reliable and Durable: Made with high-quality materials for longevity.

- Eco-Friendly: Converts food waste into useful fertilizer, contributing to sustainable practices.

For more details, visit our Restaurant Garbage Treatment Equipment page.

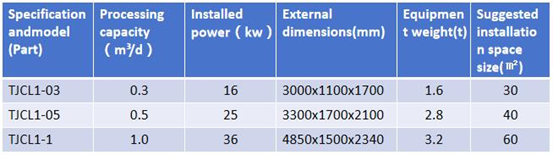

Specification and Parameters

The TJCLI system can be customized based on your specific needs. Below are the typical processing capacities and equipment specifications:

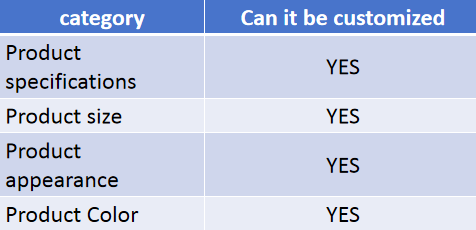

Our company can customize products according to customer requirements, with specific details as follows

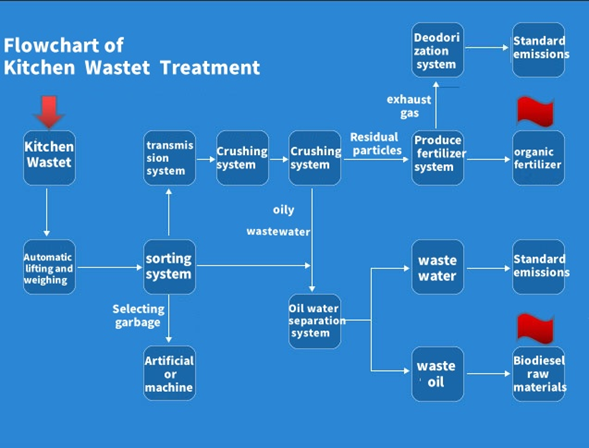

Processing Flow Chart

See how the system works from start to finish.

Contact Us for Your Tailored Waste Treatment Solution

TIAN JIAN is committed to providing efficient and environmentally friendly solutions for catering waste treatment. Reach out to us today to learn more about our fully automatic waste treatment systems and how we can help your business manage waste sustainably.

For a customized quote or consultation, contact us here.