Get Support

123-456-789-10

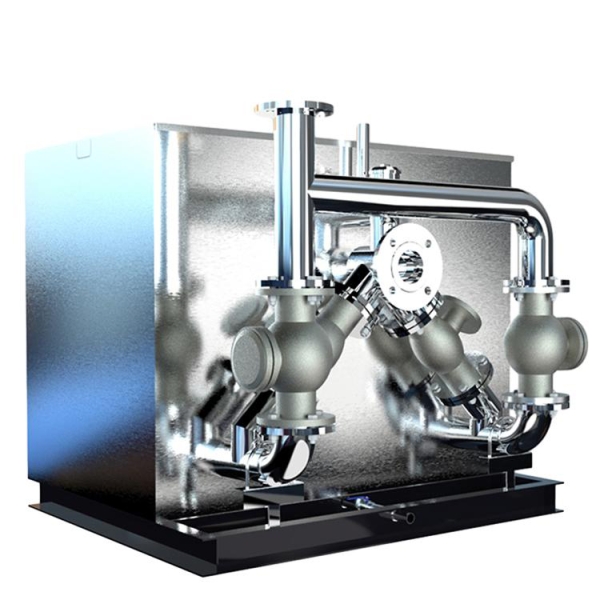

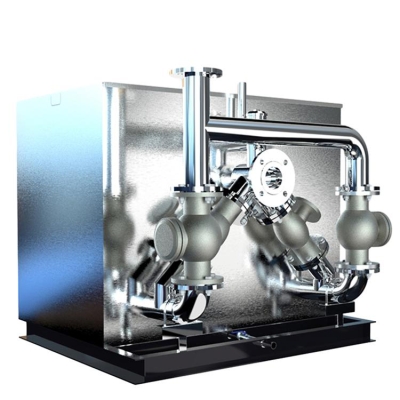

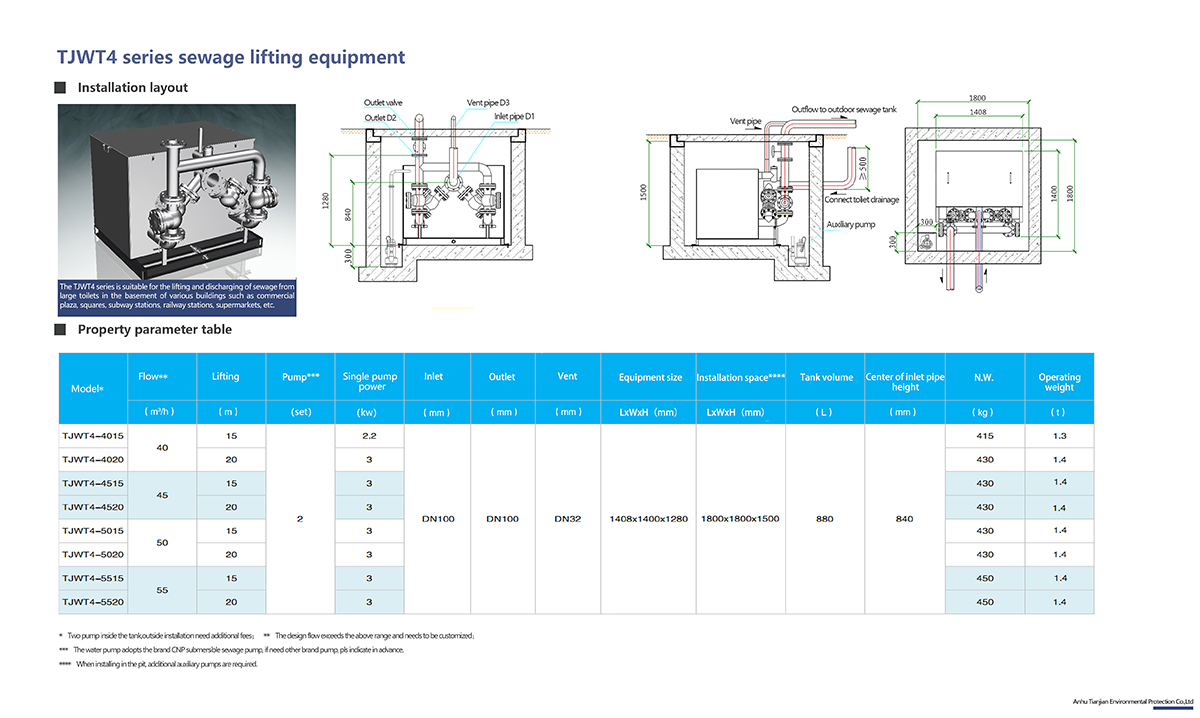

The TJWT4 Toilet Sewage Lifting Equipment is a revolutionary, intelligent sewage lifting solution developed by TIAN JIAN to manage wastewater efficiently in commercial spaces, including subways, large shopping malls, and plazas with high-volume basement toilets. This integrated system enhances performance by combining solid-liquid separation, backwashing, intelligent control, and easy maintenance.

"Integrated equipment for sewage lifting of underground toilets" is an intelligent product independently developed by Tianjian Company . In terms of design thinking, the traditional lifting method has been changed, combining the concepts of "solid-liquid separation", "backwashing", "integration" and "intelligence" to design a series of intelligent sewage lifting equipment.

Applicable Fields:

Our commercial sewage lift station pumps are specifically designed for high-flow areas such as subways, large shopping malls, and plazas, where the instantaneous wastewater flow from basement toilets is particularly high. These pumps ensure efficient and reliable sewage lifting, making them ideal for commercial environments with demanding wastewater management needs.

Key Features of the TJWT4 Commercial Sewage Lifting Equipment:

1. Intelligent and Automatic Operation

- The TJWT4 series operates automatically by monitoring water levels. The system activates the pump when the water level reaches a predetermined high level and shuts it off when it drops to a low level. This ensures consistent performance with minimal human intervention.

- Automatic pump switching between two pumps ensures reliability and efficient waste management.

2. Solid-Liquid Separation Technology

- Tianjian's solid-liquid separation technology effectively prevents the impeller from encountering harmful debris, ensuring the pump operates smoothly without damage from hard or winding objects.

- Debris Discharge: Once the pump starts, the solid-liquid separation device automatically discharges debris into an outdoor septic tank.

3. High Efficiency and Low Odor Design

- The TJWT4 is designed to prevent unpleasant odors by ensuring timely discharge of sewage and waste, preventing fermentation. The stainless steel linkage liquid level gauge controls the timely discharge, and the equipment features sealing rubber pads and ventilation measures to maintain a smell-free environment.

4. Advanced Pump Protection

- High-Insulation Pump Design: The system is equipped with high-insulation pumps that can safely operate at up to 155°C, preventing motor burnout due to frequent start-ups.

- Safety Return Device: In the rare event of a stuck check valve, the system utilizes a safety return device to prevent overflow by redirecting sewage back into the tank and activating a secondary pump.

5. Robust and Reliable Performance

- Hydraulic Model Testing: The system has undergone rigorous testing to ensure optimal functionality, with the solid-liquid separation device designed to operate without manual cleaning.

- When the solid-liquid separation device is 1/3 full, the high-sensitivity floating ball automatically signals the control system to start the pump, ensuring continuous performance without clogging.

6. Easy Maintenance and Scalability

- The TJWT4 is built with modular components, making it easy to install, maintain, and scale as needed. It also integrates with your existing infrastructure, offering a hassle-free solution for large commercial spaces.

How the TJWT4 Commercial Sewage Lifting Equipment Works

-

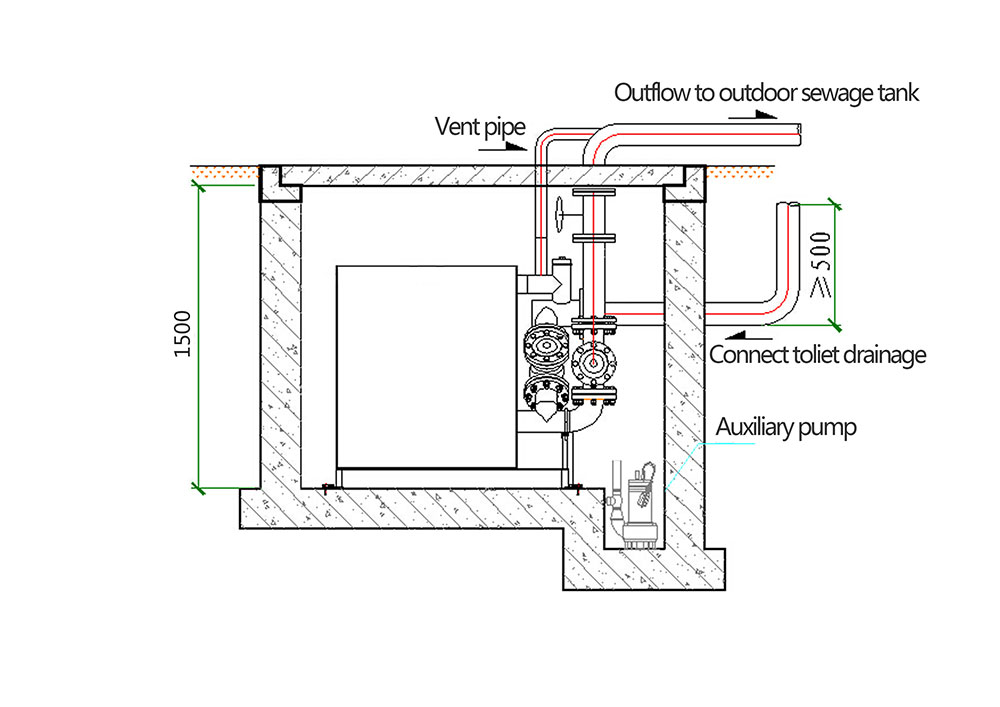

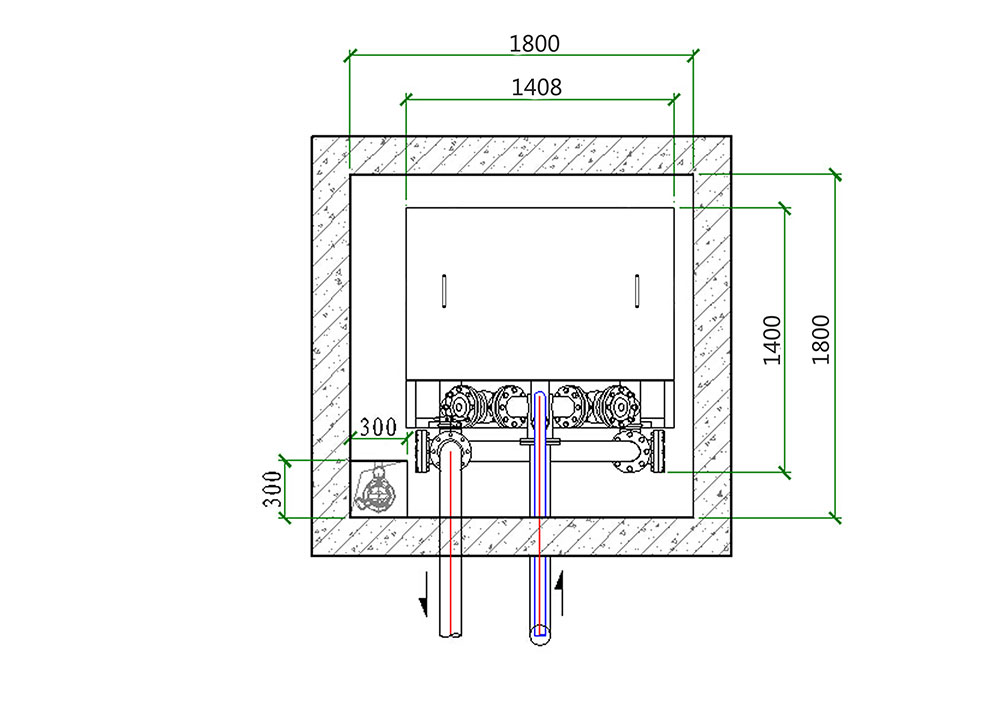

Water Inlet and Outlet: The system is easy to set up—simply connect the water inlet and outlet pipes, and the unit operates stably with minimal setup.

-

Debris Removal: The debris in the solid-liquid separation chamber is automatically discharged to the septic tank. Additionally, a high-pressure water flow is used to stir and evenly distribute sludge, preventing any buildup.

-

Overflow Prevention: With its advanced control system, the TJWT4 automatically manages overflow situations, ensuring that excess water is efficiently handled by the backup pump and an audible alarm is triggered for maintenance.

Why Choose TIAN JIAN’s TJWT4 Toilet Sewage Lifting Equipment?

- Intelligent Control: Fully automated operation with intelligent water level monitoring.

- Durable and Reliable: Designed to prevent damage to pumps and ensure long-lasting performance.

- Eco-Friendly: Minimizes odors and prevents the risk of overflow.

- Energy Efficient: High-insulation pumps and advanced designs ensure energy-saving operations.

For further details on this advanced system, visit our Toilet Sewage Lifting Equipment page.

Working principle:

1. Where does the water come from? Where did it go ?

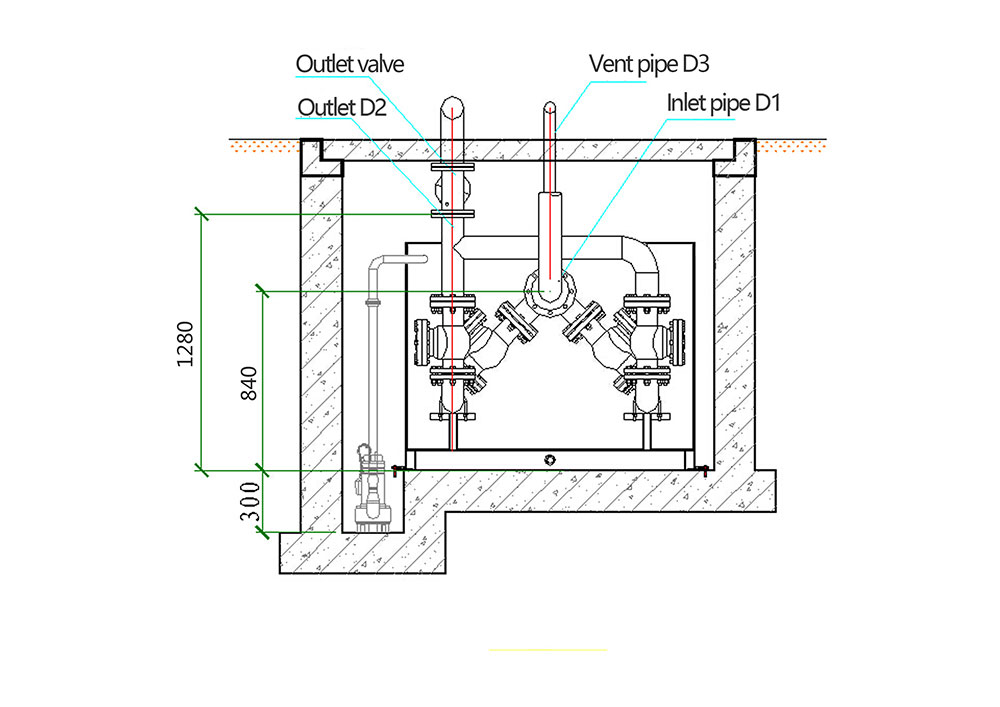

The "TJWT4 series integrated sewage lifting equipment" is an intelligent product independently developed by Tianjian Company for the sewage lifting of underground toilets. The equipment only needs to be connected to the water inlet and outlet pipe and it can operate stably after powering on. convenient!

2. How to avoid the pump burned out?

The "TJWT4 series of integrated sewage lifting equipment" has changed the traditional lifting method in design thinking. It uses Tianjian's "solid-liquid separation" technology to completely separate the impurities from the sewage, making it difficult for the impeller to touch its killer: winding objects, hard objects, to ensure the normal use of the pump , to avoid abnormal damage to the pump.

3. How to discharge the debris in the tank?

When the pump is started, the debris in the solid-liquid separation device is automatically discharged to the outdoor septic tank; at the same time , a high-pressure water flow starts to wash the bottom of the water tank, so that possible fine sludge and water in the sewage are stirred Evenly, it is lifted to the outdoor septic tank with the flow of water, without manual cleaning;

4. How to avoid overflowing odor?

We all had the experience that the toilet at home could not be flushed in time when the water was cut off: when we waited to flush again the next day, we found that the toilet smelled bad because the feces were fermented. Therefore, the "TJWT4 series of integrated sewage lifting equipment" considered at the beginning of the design that the volume of the water tank should not be too large, and then the stainless steel linkage type liquid level gauge was controlled to discharge sewage and dirt in time to avoid long-term fermentation. Coupled with sealing rubber pads and ventilation measures, the equipment works without peculiar smell.

5. How to control the work of the equipment?

"TJWT4 series integrated sewage lifting equipment" adopts intelligent control mode to automatically run: when the water level reaches a high level, the water pump starts to drain, and when it reaches a low level, the pump stops; when the next start water level is reached, another water pump starts to drain. The two water pumps are switched alternately and stand by each other, which is safe and reliable.

1. What is the relationship between the solid-liquid separation device and the volume of the water tank?

Tianjian brand "TJWT4 series integrated sewage lifting equipment" was designed and passed a very strict hydraulic model test: when the debris in the solid-liquid separation device is stored to 1/3, the high-sensitivity stainless steel rod-type floating ball feeds back to the control System signal, that is, automatically start the water pump to drain to ensure that the solid-liquid separation device will not be blocked and avoid manual cleaning. When the solid-liquid separation device is too large or too small, the solid-liquid separation device is blocked and the toilet can not be launched in time and overflows.

2. Is there anything special about the sewage lifting pump?

Thinking of the odor,the volume of the water tank was limited. However, we know that all electrical equipment is very afraid of frequent startup. When the water pump starts frequently, the temperature of the water pump motor rises too fast, and the failure of timely heat dissipation will cause the motor to burn out. Therefore, Tianjian sewage lifting equipment is equipped with a high-insulation pump: the temperature of the pump is safe to 155℃.

3. How does the equipment work when the two pumps are started at the same time?

When the toilet drainage volume is very large at a certain moment, when one pump starts to not meet the drainage demand, the second pump will automatically start the drainage to avoid the untimely leakage of sewage discharge. At this time, the toilet drain will enter the water tank through the safety return device, which will not affect the normal use of the toilet.

4. If the water inlet check valve is stuck, will the equipment overflow?

In a very small probability, the water inlet check valve is stuck and cannot be closed normally. If the water pump starts to drain at this time, the sewage will flow back to the water tank through the safety return device. Sewage continues to enter the water tank, and when it reaches an ultra-high level, another water pump starts to drain. At the same time, an audible and visual alarm signal is issued to remind the property personnel to notify our company for maintenance in time.