Get Support

123-456-789-10

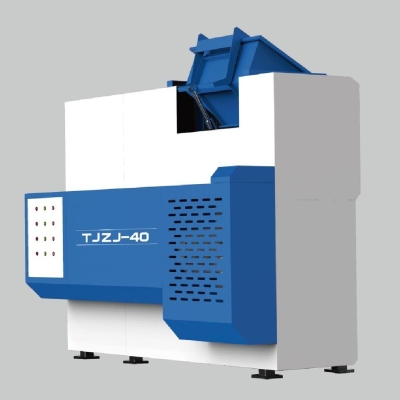

TJCY1 Series of kitchen waste pre -treatment oil and water separation equipment

Feature introductionThe local processing method can effectively remove excess wastewater and residue, and play a role in purifying and recycling oil for the first time. The equipment covers a small area, no noise at runtime, no pollution environment, easy maintenance management, low equipment cost,

- Model:

- Brand:

- Port:

- Quantity:

Feature introduction

The local processing method can effectively remove excess wastewater and residue, and play a role in purifying and recycling oil for the first time. The equipment covers a small area, no noise at runtime, no pollution environment, easy maintenance management, low equipment cost, and high economic benefits. It is widely used in the purity of animal and plant oils such as water oil and oil, oil -barrier, and oil -proof ponds. A series of problems.

1. It has the characteristics of high -efficiency oil and water separation, water miscellaneous separation, convenient oil discharge sewage and discharge, integrated integration, wide range of applications, strong compatibility, and good separation performance;

2. Meet the requirements of 3%to 4%(kitchen garbage wastewater) requirements in the line;

3. The pre -processing system with the dining and kitchen project (5 tons and above) is used to reduce the disorderly discharge of oil pollution, and the recycling of regular channels of waste oil;

4. Reasonable operation and operation, effectively take the technical measures of energy saving and efficiency and efficiency;

5. The far -infrared heating method is adopted. Electric thermal efficiency is high, energy saving and environmental protection;

6, long life and high reliability: the design surface power load is low, and multiple protection is used, which greatly increases the safety and life of electric heater;

7. High safety performance: no bright fire, external protection, insulation, higher safety;

8. Two sections of loop control, parallel work, do not affect each other;

9. The installation is convenient and flexible, and the maintenance is convenient;

10. The size of the whole machine meets the requirements of on -site reserved space.

1 |

Model specification: TJCY1-2/3/5 |

7 |

Medical: Kitchen wastewater (water oil, oil -barrier/pool recycling oil), |

2 |

Single rated processing range: 2 ~ 5M |

8 |

Method: Self -current/pressure flow, no special corrosive liquid |

3 |

Heating method: carbon fiber, far infrared radiation |

9 |

Installation requirements: flat, above the fire source 5.0m or more |

4 |

Preheating box can: SUS304 |

10 |

Power voltage: 380V ± 10%, power supply frequency: 50Hz ± 5% |

5 |

Electric heating temperature: <500 ℃ |

11 |

Interface and method: oil discharge DN50, drainage, residue DN100 hand -control warfare |

6 |

Heating temperature: 50 ~ 70 ℃ |

12 |

Electric thermal efficiency:> 96%; power factor cos> 0.98 |

The kitchen waste water generated during the treatment of kitchen waste uses preheating sedimentation-gravity separation recycling method: to maintain the liquidity of wastewater through preheating and sedimentation of carbon fiber, melt waste oil, and separate water, oil, and slag for a short time. Most of the floating oil enters the far -infrared heating separation cannibal recycling tank through special oil guide weir flow tract, immerse the internal oil of the kitchen garbage, and then separates the gravity subtraction. "(Waste residue)," light liquid phase "(waste oil) and" heavy liquid "(heavy liquid phase" (kitchen wastewater) separation.