Get Support

123-456-789-10

Application :

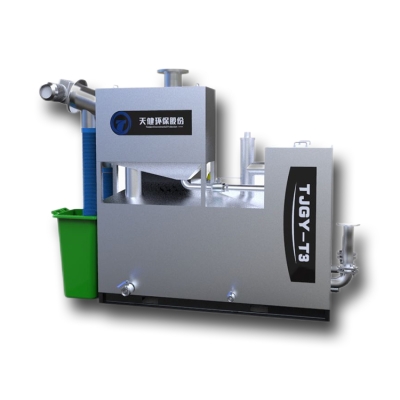

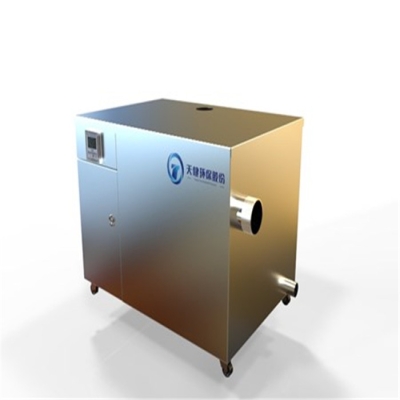

Automatic cooking oil water separator is widely applicated to large scale buildings, including (basement or underground) commercial complex, living square, Department store, large supermarket, hotel, hospital, army, school,office building, apartment, station, airport, industrial park, restaurant, food plaza and other places containing oily sewage. The size of the equipment can be customized according to different users, different displacement and different working conditions. Equipment configuration can be configured according to customer preferences.

1. How to ensure the effectiveness of oil-water separation?

Tianjian's "TJGT6 series fully automatic oil separation and lifting intelligent equipment" adopts a hierarchical oil-water separation process upgraded from the sixth stage oil-water separation process of the third-generation T3 series oil separation equipment, effectively removing 80% of floating oil and 15% of emulsified oil in the oil. The oil content in the effluent is less than 100mg/L, which meets national standards.

2. Where does water come from? Where did it come from again? Is installation convenient?

TJGT6 series fully automatic oil separation and lifting intelligent equipment "is an intelligent product specially designed by Tianjian Company for the treatment of underground catering wastewater. The equipment only needs to be simply connected to the inlet and outlet of the equipment during installation, and can operate stably when powered on. Installation is very convenient!

3. How to control the generation and spread of odors?

The fundamental reason for the foul odor of catering oil separation equipment is that food waste is not cleaned up in a timely manner, and after entering the oil-water separation chamber, it undergoes long-term fermentation, resulting in the production of fatty acids and causing foul odor. Our Tianjian company's oil separation lifting equipment has undergone three-level treatment in the early stage to remove odors, and with sealing and ventilation measures, we have created a conscientious product that is odorless, environmentally friendly, and reliable.

4. How to discharge grease?

Tianjian's "TJGT6 series fully automatic oil separation and lifting intelligent equipment" has changed its design concept from the traditional three-stage oil separation that requires manual salvage. It uses the asymmetric conical structure above the oil-water separation zone to concentrate the oil, and then uses a chain automatic oil discharge mechanism to discharge it into a dedicated closed oil drum for centralized transportation. It basically does not require manual salvage of floating oil and emulsified oil, and has low operating costs and high efficiency. The equipment comes with a constant temperature electric heating device, which avoids the disadvantage of animal fat solidification and smooth discharge; The equipment also comes with a manual oil discharge device.

5. How does the control system work?

The intelligent management and control system of Tianjian's "TJGT6 series fully automatic oil separation and lifting intelligent equipment" adopts PCU microcontroller control, and the operating status is displayed in Chinese. Its highlight is process linkage control: it automatically starts the slag removal machine, oil discharge device, heating device, and drainage device when there is a processing demand according to the processing requirements, without causing waste of power resources. The system adopts a magnetic liquid level detection device and has functions such as multi-point monitoring, automatic alarm, overload and short circuit protection, signal remote transmission (BA interface), and water pump water shortage protection.

Specification and Parameter

| Parameter | Value/Range |

|---|---|

| Flow range | 15~55 m³/h |

| Ambient temperature | 0~55℃ |

| Supply voltage | 380V ±10% |

| Inlet diameter | DN100-150 |

| Outlet Diameter | DN65-100 |

| Medium temperature | ≥5℃ |

| Model Specification | Flow Rate (L/s) | Lift Head (m) | Number of Pumps | Total Power (kW) | Equipment Dimensions (LxWxH) (mm) | Installation Dimensions (LxWxH) (mm) | Effective Volume (L) | Inlet Pipe Center Elevation h1 (mm) | Equipment Weight (kg) | Operating Weight (t) |

|---|---|---|---|---|---|---|---|---|---|---|

| TJGT6-715 | 15 | 2 | 4.43 | 3000x1500x2100 | 3900x2500x2500 | 1800 | 810 | |||

| TJGT6-720 | 7/25 | 20 | 5.83 | 3000x1500x2100 | 3900x2500x2500 | 1800 | 840 | 3.3 | ||

| TJGT6-725 | 25 | 2 | 7.43 | 880 | ||||||

| TJGT6-1115 | 15 | 2 | 4.43 | 900 | ||||||

| TJGT6-1120 | 11/40 | 20 | 5.83 | 3400x1800x2100 | 4300x2800x2500 | 2650 | 2020 | 930 | 4.3 | |

| TJGT6-1125 | 25 | 2 | 9.43 | 950 | ||||||

| TJGT6-1520 | 15/55 | 20 | 5.83 | 3960x1800x2100 | 4900x2800x2500 | 3200 | 1030 | 5 | ||

| TJGT6-1525 | 25 | 2 | 9.43 | 1110 |

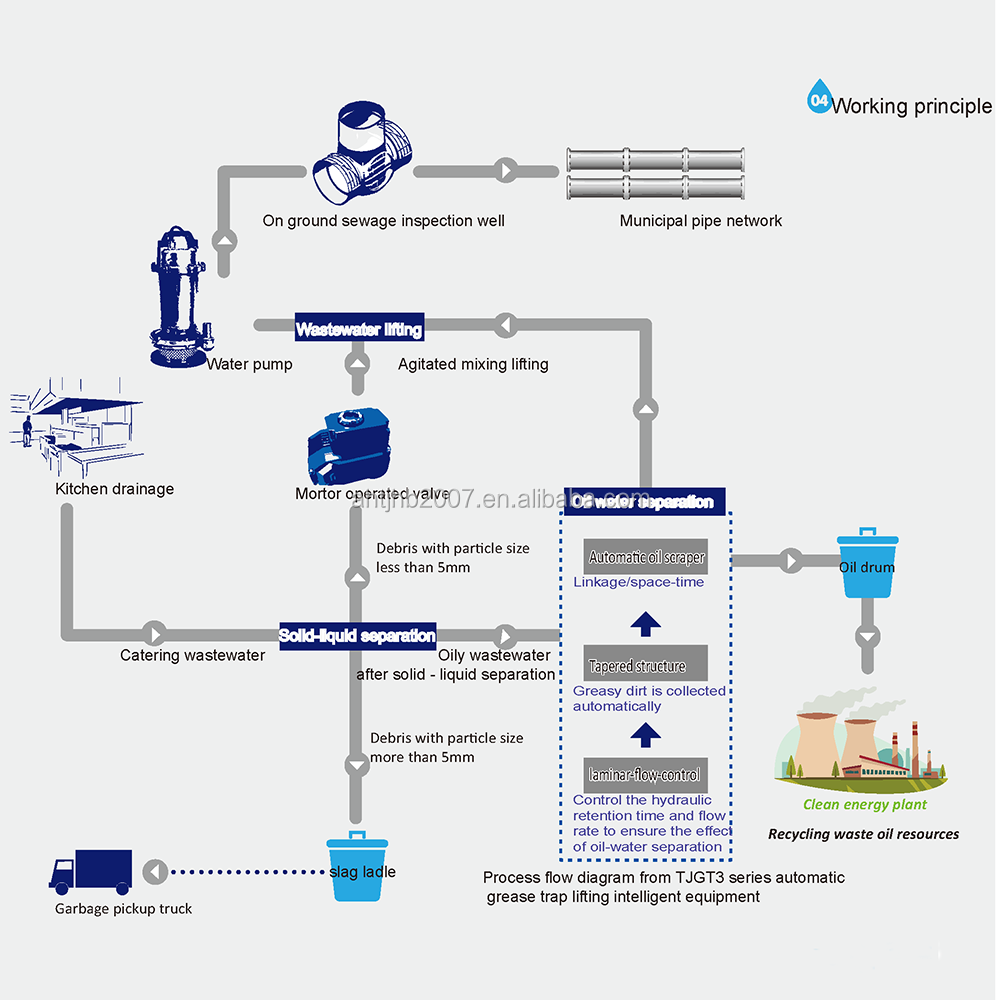

Processing flow chart